Calculating the cost of running a 3D printer per hour can vary depending on various factors, such as the type of printer and the materials used. To give an idea of the average cost, we’ve estimated the electricity and filament costs used over the past few months.

Based on our calculations:

- 3D printers typically consume around 55 watts per hour or 0.055 kilowatt-hours. Using the average electricity cost of 13 cents per kilowatt-hour, the monthly cost of electricity for a 3D printer that’s used 12 hours per day would be approximately $3.

- The filament cost is another factor to consider, and the most commonly used 3D printer filaments usually range from $30-$45 per 1KG. Assuming an average consumption rate of 1.5kg per month, the filament cost would range from $45-$70.

It’s interesting to note that the power consumption of 3D printers is comparable to that of incandescent bulbs, and with proper management, the cost of running a 3D printer can be kept to a minimum.

3D Printer cost to run: Power/ Electricity Consumed By A 3D Printer

In our testing, we wanted to determine the impact of different operating temperature settings and bed temperature settings on the power consumption of 3D printers. To do this, we purchased an intelligent power meter from Amazon and measured the watt usage at various settings. Our findings showed that turning off the bed temperature resulted in significant power savings and had little to no impact on the quality of the prints.

When the bed was turned off, we observed an average power consumption of 0.55 kWh per 10 hours. We conducted this test using the Creality Ender 3 Pro, which is priced at around $250. We repeated the test with the bed at different temperature settings and found that keeping it at the highest temperature setting resulted in power consumption that was twice as high as when it was turned off. However, when we kept the bed at medium settings, the power consumption was significantly lower than at the highest temperature setting.

It’s worth noting that our results are specific to the Creality Ender 3 Pro, and other 3D printers may have different power consumption profiles. However, our findings suggest that keeping the bed at the highest temperature setting consumed twice the amount of power than when it was turned off. It consumed fairly less than the higher settings when we kept it at medium settings.

So there is a direct correlation in the consumption of power when the temperature of the bad is turned off and when it is at its highest temperature setting.

But does the temperature of the bed affects the 3D print?

The impact of bed temperature on 3D printing is a topic of interest for many users. Our experiment showed that keeping the bed temperature at the maximum setting may result in cracks in the printed object upon cooling down. We found that the best results were achieved when the bed temperature was set to medium or even turned off altogether.

In terms of cost, using a 3D printer for 10 hours a day can cost between $2 and $4, depending on the bed temperature settings and the cost of power in your area. To calculate the cost of power, simply multiply the total kilowatt-hour used in a month by the cost per kilowatt-hour in your area.

For example, if the average cost of power in your area is 13 cents, and you use your printer for 10 hours a day for 30 days, it will consume 16.5 kilowatt-hours, resulting in a cost of $2.15 when the bed is turned off. If you use the printer with the bed set to medium temperature, the cost would roughly double to $4.

It’s important to keep in mind that the cost of power can vary widely depending on location, so it’s a good idea to check your local rates to get a more accurate estimate. Overall, the bed temperature setting and power consumption are important considerations when using a 3D printer, and finding the optimal settings can help ensure the best quality prints at a reasonable cost.

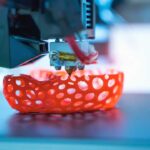

3D Printer Material Cost Per Gram/ Per Metre

The world of 3D printing materials is vast, with various options available for different needs and budgets. Some of the most commonly used materials include PLA, ABS, PETG, Nylon, TPU, TPE, ASA, Resin, Polycarbonate, and other specialty materials. The cost of these materials can range from as low as $5 to as high as $1000 per kg, depending on the type, quality, and quantity required.

In our experience, the most frequently used materials for 3D printing are PLA, ABS, and Resin. Resin is typically more expensive than PLA and other filaments, but it also offers superior quality and precision for certain applications. For those on a tight budget, there are affordable options available, with some filaments costing under $10 per kg. We’ve even found great budget options for those not looking to buy in bulk.

When selecting a 3D printing material, it’s important to consider factors such as strength, flexibility, heat resistance, and print quality. Additionally, some materials may require specialized printing settings or equipment, so it’s important to do your research before making a purchase. By understanding your needs and budget, you can choose the best material for your specific project and get the most out of your 3D printer.

What is the cheapest material or filament for the 3D printer?

When it comes to 3D printing, the type of filament used can have a significant impact on the final product’s quality and cost. Typically, the white filament is cheaper than colored filaments, and it’s essential to consider the cost of the filaments when selecting a 3D printer.

One option that has stood out to us is the rainbow printer filament we found on Amazon. Although the cost can vary, Resins, ASA, and Polycarbonate typically cost around $50 per kg, while the best quality PLA, such as soft PLA, can cost around $100 per kg. It’s important to consider the quality and properties of the filament when making a selection, as it can affect the print’s durability, flexibility, and overall performance.

For those seeking high-quality output, Resin is a good choice, but other filaments can also produce excellent results, depending on the project’s requirements. We prefer to use Resin and soft PLA when we need extreme quality and use other, more affordable filaments for general purposes. It’s important to note that the cost of the filament is only one aspect to consider, as different filaments can have varying print speeds, adhesion properties, and post-processing requirements.

It’s also worth considering the amount of time and energy required to print an object or figure. Depending on the size and complexity of the design, a typical object or figure of 150g can take 10-20 hours to print, and the cost can range from $2-$4. Ultimately, selecting the right filament and understanding the associated costs and time commitments are essential for achieving the desired results in 3D printing.

Other Miscellaneous Costs.

Efficiently using a 3D printer requires a few additional products, such as safety gloves and alcohol, to clean the bed. These items are basic household necessities and won’t cost you much at all, just a few cents.

Investing in these small but important items can help you maintain a clean and safe printing environment, ultimately improving the quality of your prints and prolonging the lifespan of your printer. So, it’s worth considering adding these items to your toolkit if you haven’t already.

Cost of Maintenance of the 3D Printer

Maintaining a 3D printer is an essential aspect of owning one. Although it may not require frequent maintenance, it is crucial to keep an eye on its performance to ensure it functions correctly. Maintenance procedures are not only affordable but also easy to perform, and with a little attention, one can avoid costly repairs.

Regular maintenance involves checking that all the printer’s components are tight and lubricated, particularly the lead screws, which are responsible for moving the printer’s head along the X, Y, and Z-axis. Lubrication reduces friction and ensures that the printer’s head moves smoothly and accurately, thus enhancing print quality.

The extruder head and nozzle are the most common parts that need replacing. The extruder head melts the filament and pushes it through the nozzle to create the 3D object. Filament clogs are the #1 killer of extruder heads, and it is essential to clean them regularly to avoid clogs. The filament can sometimes be abrasive, and materials like glow-in-the-dark and carbon fiber can cause wear and tear on the extruder head. This wear and tear can lead to an increase in nozzle diameter, which can result in poor print quality. Nozzles are quite cheap, and a basic brass replacement can cost around $3, making them affordable to replace.

In summary, maintaining a 3D printer is critical to ensure that it functions optimally and produces high-quality prints. Regular checks and lubrication of the printer’s components, particularly the lead screws, are essential. In case of any malfunction, the extruder head and nozzle are the most common parts that require replacing. By taking these simple steps, one can avoid costly repairs and ensure the longevity of their 3D printer.

Smart plug: Verify the cost of running a 3D printer!

We took the extra step of purchasing a smart plug to track the power consumption of the 3D printer, just to double-check our calculations. As expected, the results showed that the power usage was consistent with the estimated cost we had previously calculated.

For those who are concerned about the cost of running a 3D printer, it’s important to note that most 3D printers don’t make a significant difference in your energy bills. In fact, they are comparable to common household bulbs in terms of energy consumption. Based on our calculations, if you were to use the printer’s heat bed regularly, it would cost around $30 per year.

However, it’s worth considering that 3D printers do produce some amount of heat, which can impact the temperature in the room. This, in turn, may cause your air conditioning system to work a bit harder to maintain the desired temperature. We haven’t calculated the exact difference that this would make in the overall energy bill, but we believe that it wouldn’t be significant enough to cause concern.

In summary, while it’s always a good idea to be mindful of energy usage, running a 3D printer shouldn’t significantly impact your energy bills. With proper use and maintenance, the cost of running a 3D printer should be well within a reasonable range.